Sand Casting Recipes: A Comprehensive Guide

Learn how to make your own casting sand at home from easy-to-source ingredients. 3 different formulas for you to try!

The process of sand casting has been around for a very long time, one of the oldest castings is of a copper frog, believed to be made around 5000 years ago (3200 BCE) in Mesopotamia.

While the process of sand casting commercially has changed greatly due to technological advances, casting at home is very similar to how our ancestors would have done it.

In this comprehensive guide, we will cover many casting sand recipes from the most basic using widely available materials to more complicated recipes with more difficult materials to find.

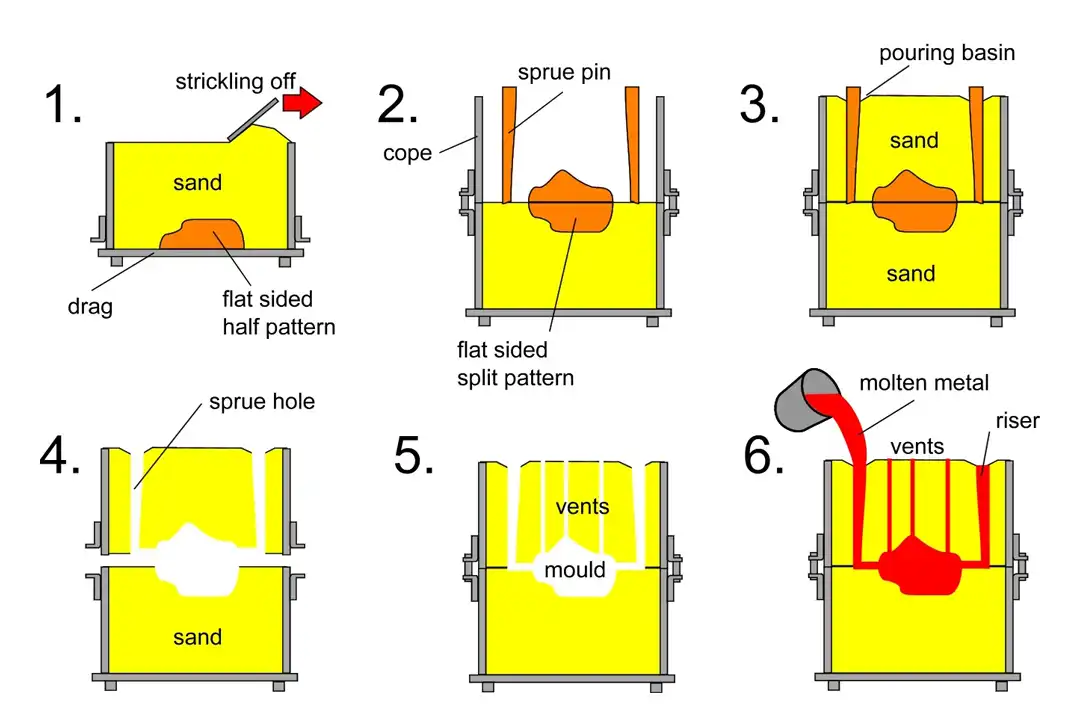

What is sand casting?

Sand casting is a process where molten metal is poured into a sand mold to create the desired shape, this shape is also known as a positive due to how it interacts with the mold which is a negative of the shape.

A flask that detaches in two, has one side filled with sand, and the shape is pushed into the flask halfway (or the sand is carefully packed around it depending on the shape) the mold is formed by the sand around the shape.

The flask half with the shape packed with sand is then dusted with a releasing agent like talcum powder and the other flask half is placed on top and sand is packed in until it is fully level with the flask.

Pouring and air vent holes are added to the sand mold.

The flask halves are then carefully separated and the positive (shape) is removed before the flask is re-assembled and held together with clamps or pins.

The sand mold is now ready for pouring!

Casting sand can withstand the high temperatures of molten metal while retaining the shape of the mold. Sand is abundant and widely available, allowing for a cost-effective way of creating complex metal objects.

Types of casting sand

- Green Sand is mainly sand, clay water, and other additives.

- Petrobond - is oil-based.

- Coal dust sand

The term ‘green’ refers to the weak and plastic condition of the sand. This is the most common and cheapest type of sand available for mold making.

Casting Sand Recipe #1 - The Basic Recipe

This is the most basic casting sand recipe and can be made with materials that are widely available, if you are having trouble finding the materials that make the other recipes this will be a good fallback.

Formula (By weight, not volume):

- 70% of Sand (from the ground or store brought)

- 30 % of Clay (from the ground or store brought)

- Water

Unlike most recipes that suggest you should completely follow the instructions to the letter, I encourage you to experiment with the composition of this basic recipe. In different parts of the world, you will get different clay and sand, so you will need to tweak the recipe to suit if you have brown clay try the following above, if you have home-dug green clay try as low as 15% clay you will need to find out what works for you (for store brought bentonite clay try around 5% - 10%).

Instructions

You can either purchase the sand and clay from a hardware store or you can procure the clay by digging up a small clay deposit in your garden, If possible I'd recommend purchasing fine sand instead of collecting it from a freshwater river (don't use sand with salt in it). Your local para pool dealer should be able to point you in the right direction as they use fine sand under para swimming pools to protect the liner and smooth out the bottom.

The finer and debris free the sand is the better, both the clay and the sand should be dry if they are damp, leave them out to dry for a few days (the clay might need to be broken up).

If you have collected the sand and clay yourself you will need to sift the sand with a sieve to reduce it to the finest and purest form you can, this will help produce much more detailed molds.

The clay will also need to be "purified" by removing all contaminants and broken down to fine dust, a setup similar to a mortar and pestle should aid the process.

How to mix:

Use a scale, mix by weight, not volume!

Metric example: if you want to make 1 kg of casting sand you would need 700 grams of sand and 300 grams of clay (if brown clay)

Imperial example: For every 1 pound of casting sand you want to make you would need 11.2 ounces of sand and 4.8 ounces of clay (if brown clay)

Mix the sand and clay together spraying water sparingly until the clay is able to maintain a solid form, to test this squeeze some of the mixture into a ball with your hand, if it clumps together (but doesn't stick to your hands, then it's too wet) your casting sand is ready, this texture is perfect for sand casting.

Don't add too much water, water, and molten metals don't go well together. This guide is for education purposes only, take your time to research and put in place proper safety measures when working in dangerous environments with molten metals.

When casting use Eye protection, Fire retardant gloves, and wear suitable footwear in a well-ventilated outdoor area away from flammable hazards, children, and animals.

Casting Sand Recipe #2 - Fragrance-free cat litter (Not a joke)

Make sure the cat litter is made from Bentonite clay. You don't have to use cat litter if you can buy powdered bentonite from a pottery supply or other supplier but I'm assuming it's harder to come by than bentonite-based cat litter.

Bentonite clay (which is green) makes for a better binder than brown clay and therefore requires less clay in the mixture. Bentonite clay is usually formed over time from volcanic ash in seawater.

When casting with a green sand recipe that contains bentonite clay always discard the surrounding sand of the mold that has come into direct contact with the molten metal, as it will no longer work as a suitable binder due to the degradation of bentonite structure from the heat transfer.

Formula (By weight, not volume):

- 90% Sand

- 10% Unscented cat Litter (Process to about the size of fine sugar)

- Water in a spray bottle

The mixture ratios can vary, depending on your clay and sand use the formula above as a base guide. if you don't have very fine sand up the amount of bentonite clay (cat litter) you use.

Just like recipe #1 we will need to process both materials to the finest form we can manage. You can save yourself a lot of time by purchasing fine sand, to begin with (both aquarium sand and fine para pool sand will be suitable).

For coarse sand, you will still need a strainer with a fine mesh and a bucket, sift all the sand you need into the bucket. This will take some time but the extra detail in your molds will be worth it.

To process the Bentonite clay you can use a sacrificial blender (as it will wreck your blender)and blend it into a fine powder or partially fill a freezer bag and hit it with a rubber or wooden mallet.

If you choose to blend it I'd recommend using a dust mask to protect your lungs, you only have two!

How to mix:

Again this recipe is by weight, not volume, so if you want 1kg of casting sand you will need 900grams of sand and 100grams of fine bentonite powder (cat litter).

And for all you "imperialists" to make 1 Lb (16 ounces) of casting sand you will need 14.4oz of sand and 1.6oz of fine bentonite powder (cat litter).

Thoroughly mix together, either with the sacrificial blender in small portions, transferring it from cup to cup, or shaking it in a bucket.

Now the important part, adding the water the secret is you want it moist, not wet.

Spread the sand out so it has a larger surface area, then adjust the nozzle of the spray bottle to create a fine mist, gently mist the top of the sand until it changes color then stir in the damp sand with the dry sand under until it looks dry again.

Keep repeating this process until the sand clumps together when you make a ball with your hands, if the sand's consistency looks like it would be good to make a sand castle then it's ready.

Troubleshooting:

If the casting sand doesn't seem to hold a form, add more bentonite clay if that doesn't work ask yourself if your mixture is too coarse or not moist enough.

If the casting sand is too wet add more dry sand and clay at the ratio you are using.

Casting Sand Recipe #3 - Oil-based sand binder.

A lot of oil-based casting sand produces smoke during the casting process from the burning of the oil which isn't pleasant for the following recipe called K-bond (called that as it was developed in Kent state). If you are new to sand casting I would stick to the water-based recipes.

Formula (By weight, not volume):

Imperial:

- 100 lbs of sand - 100 mesh or finer

- 6 lbs of bentone clay*** (such as Bentone 34 or VG-69)

- 3 lbs of synthetic 2-cycle motor oil

- 0.2 lbs of (3.2 fluid oz) Methanol (dry gas)

Metric:

- 45kg of sand - 100 mesh or finer

- 2.72kg of bentone clay*** (such as Bentone 34 or VG-69)

- 3 liters of synthetic 2-cycle motor oil

- 95ml of Methanol (dry gas)

***Note bentone clay is an organic derivative of bentonite clay.

Method

Mix the clay and sand together while wearing a dust mask adding the motor oil in afterward.

Make small batches of less than 5kg (10 pounds) at a time, mixing by hand while wearing rubber gloves. The small batches can also be done with a throwaway old kitchen mixer.

Mix in the Methanol alcohol thoroughly.

This casting sand will become more malleable and easy to handle over time with repeated use.

The sand won't look like it bonds well until the alcohol has done its part. If the casting sand becomes less usable and isn't bonding well add more Methanol.

Summary

Making your own casting sand and casting at home can be very affordable and rewarding. A great hobby that can even generate some beer money!

If you have made your own casting sand or are thinking of casting something at home let us know in the comments below, we would love to hear about it!

Always take care when handling molten metal and dangerous tools it only takes one small mistake to permanently ruin your life or the life of others around you. Take preventive measures and use every piece of safety gear at your disposal.

You may also be interested in another article I have written about the sand-casting process and another way to make green sand.